Many Industrial IoT solutions focus on monitoring either extremely expensive equipment, or equipment that requires material replenishment: specialized gases, packaging material, even carwash detergent. Unfortunately this means a large portion, up to 95%, of industrial machinery misses out on the analytics, maintenance, and workforce optimization that IIoT applications provide.

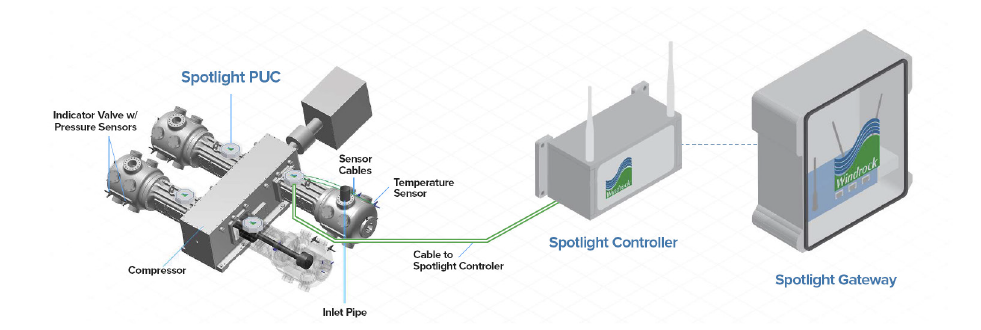

Fortunately, Windrock’s Spotlight Monitoring System allows operators to create an affordable, easy-to-install monitoring system specifically designed for rotating and reciprocating equipment. The system is composed of:

- Spotlight Peripheral Universal Connection (or PUC) magnetic mounted sensors send data over wires to the:

- Spotlight Controller, which acts as the central nervous system and transmits communicates over Wi-Fi with the:

- Spotlight Gateway, based on the Advantech Czech s.r.o. SmartFlex LTE router, which connects to the Spotlight dashboard and other Windrock analytics tools over LTE.

The SmartFlex LTE router acts as a Wi-Fi hotspot for the Spotlight PUC sensors. It was an ideal choice for the Windrock Spotlight System for several reasons:

- Carrier-flexibility means the SmartFlex operates on all major networks in North America

- Class I Div 2 and ATEX certification enables the SmartFlex to be used in hazardous oil/gas environments

- SmartFlex is an open, Linux-based system designed to host custom software applications

- SmartFlex uses an industrial temperature rated Wi-Fi radio which supports in harsh industrial environments

- Microsoft Azure certification ensures sensitive data is protected